The Sparkle Lie: Just 7% of Diamonds Shine

By Gary A.

Edited by Olivia H.

Published Aug 8, 2024

Edited on Mar 31, 2025

Industrial diamonds may not dazzle in jewelry, but their strength and versatility make them indispensable in industries ranging from manufacturing to technology. Let’s explore their fascinating role.

Navigate This Guide:

- 9 Quick Tips for understanding Industrial to I1 Diamonds: Making an Informed Choice

- Introduction

- The Unseen Heroes: Defining Industrial Diamonds

- The Multifaceted World of Diamonds: Types and Treasures

- The Economics of Diamonds: Value Beyond the Vault

- Looking Forward: The Future of Diamonds in Industry and Innovation

- Our Expert Take: The Lasting Legacy of Diamonds

- 7 Frequently Asked Questions About Industrial Diamonds

Before we dive deeper into the specifics, here are some practical tips to help guide your decision-making process:

9 Quick Tips for understanding Industrial to I1 Diamonds: Making an Informed Choice

Industrial diamonds, known for their use in heavy-duty applications, are not typically suited for jewelry due to their lack of visual appeal and higher presence of inclusions. However, if you’re looking for a more affordable option that still offers the charm and brilliance of a diamond, I1 diamonds are a great alternative. These diamonds bridge the gap between industrial-grade and higher-clarity diamonds, providing a visually appealing and budget-friendly choice for engagement rings.

I1 diamonds are a great alternative to industrial diamonds when seeking an affordable and visually appealing option for engagement rings. While they have visible inclusions, choosing wisely can result in a beautiful ring.

Tip 1: Inclusions and Eye-Clean Appearance

– Inclusions: I1 diamonds have inclusions visible to the naked eye. Look for diamonds where inclusions are located in less noticeable areas.

– Eye-Clean: Focus on finding an I1 diamond that appears clean to the naked eye from a reasonable distance. Inclusions near the edges can be hidden by prongs or settings.

Tip 2: Impact on Durability

– Durability: Ensure the inclusions do not compromise the diamond’s structural integrity. Avoid large inclusions that reach the surface, as they can make the diamond more prone to chipping.

Tip 3: Importance of a Good Cut Quality

– Cut Quality: A well-cut I1 diamond can mask some inclusions and enhance brilliance, making the diamond appear more attractive. Prioritize cut quality over carat weight or clarity.

Tip 4: Balancing Color and Clarity

– Color Grade: Since I1 diamonds have clarity imperfections, opt for a higher color grade (G-H) to ensure the diamond looks more appealing overall.

Tip 5: Choosing the Right Setting and Metal

– Prong Settings: Use prong settings to hide inclusions and enhance the diamond’s appearance. Consider halo or bezel settings to draw attention away from imperfections.

Tip 6: Metal Color Impact

– Metal Choice: The color of the metal band can affect the appearance of the diamond. White metals like platinum or white gold can enhance the diamond’s brilliance, while yellow or rose gold can complement the diamond’s natural color.

Tip 7: Importance of Certification

– Certifications: Always buy a certified I1 diamond from a reputable grading authority (GIA, AGS). Certification ensures the diamond’s quality and authenticity.

Tip 8: Maximizing Your Budget

– Value for Money: I1 diamonds offer great value for those on a budget. Focus on finding a well-cut diamond with good color and strategically placed inclusions to maximize beauty and value.

Tip 9: Considering Enhancements and Treatments

– Treatments: Be aware of clarity-enhanced diamonds. These treatments can improve the appearance but might affect durability and require special care.

Now that you’ve got these practical tips, use Jeweler AI below to find the perfect engagement ring that suits your style and budget:

Introduction

Discover the hidden world of industrial diamonds and learn how they revolutionize technology and industry beyond jewelry in this comprehensive guide.

We obviously talk a lot about the beauty, elegance, and brilliance of diamonds. For many of us, these are precious jewels that appear from the earth, destined to remain a lifetime upon our fingers, symbolising everything from love and purity to elegance and luxury.

But while we might be hung up on the four C’s and how well a diamond sparkles, there are many people who see diamonds a little differently. Diamonds aren’t just beautiful objects to gaze at, they’re strong industrial tools that are valued for their various applications.

The Unseen Heroes: Defining Industrial Diamonds

For those unaware, industrial diamonds are diamonds used for purposes other than jewelry – cutting, grinding, and drilling, in industries ranging from manufacturing and construction to electronics and mining. These diamonds are known for their alternate characteristics: hardness over beauty, and thermal conductivity over brilliance.

They’re used to manufacture cutting tools, grinding wheels, and drilling machinery, or used as abrasives for powders and polishing compounds. They’re used for their high thermal conductivity, forming thermal management components in electronic devices, laser systems, and high-power applications where efficient heat dissipation is crucial.

They’re embedded in cutting and sawing wire, and used in construction industries to cut through hard materials with minimal loss. They’re used in exploration drilling for oil and gas, mineral exploration and geological surveys.

They’re used in the manufacturing of dental drills, surgical blades, and other medical instruments where their hardness and biocompatibility are pivotal. Across multiple industries around the world, industrial diamonds are a resource that can aid numerous processes, and operations, improve efficiency, and drive innovation into the stratosphere. Sure, only 7% sparkle. But that’s irrelevant when it comes to what they can do.

The Multifaceted World of Diamonds: Types and Treasures

There. Phew. The point is: industrial diamonds are constantly working behind the scenes, improving our daily lives and streamlining the tasks of millions of workers. Just as there are in the world of jewelry, however, there are many different types of diamonds that make this happen.

The first to talk about are natural diamonds – diamonds that are formed through geological processes deep within the Earth’s mantle. These kinds of diamonds are treasured for their exceptional hardness – scoring a perfect 10 on the Mohs scale of mineral hardness – making them the ideal candidate for construction work such as cutting, grinding, and drilling materials like metal, ceramic and stone.

On the other hand, many industries opt for synthetic diamonds – diamonds that are formed in a laboratory through controlled processes. These kinds of diamonds offer consistent quality and properties, making them perfect for more precise industrial applications where uniformity is a must.

From the Earth to Industry: Natural vs Synthetic Diamonds

The question of which diamond is ‘better’ is a common one, but often irrelevant – hence why we’ve dedicated a whole sub-heading to it. Hmm. Really, it depends on the specific requirements of the application and the desired properties being sought after.

As mentioned previously, natural diamonds are one of the hardest known materials, but they also have high thermal conductivity, allowing them to efficiently dissipate heat during machining processes. They are also known to be highly resistant to abrasion and wear, which maintains their sharpness and cutting efficiency under harsh conditions and allows for longer tool life and higher productivity in the industrial space.

Synthetic diamonds, as mentioned before, are consistent. Because they’re grown in a controlled setting, it’s more likely that the diamonds will be uniform and perfect for the specific task at hand. It also means that they’re customisable, with the size, shape and properties of synthetic diamonds often tailored to meet diverse industrial needs. Furthermore, synthetic diamonds are far more cost-effective, which is crucial for industries looking for diamonds in bulk.

Ballas, Bort, and Carbonado: The Industrial Trio

This is all without mentioning the specific types of natural diamonds. Ballas, bort, and carbonado are not the names of three wacky characters in a discontinued sitcom, these are three different forms of industrial diamonds that are valued for their unique characteristics.

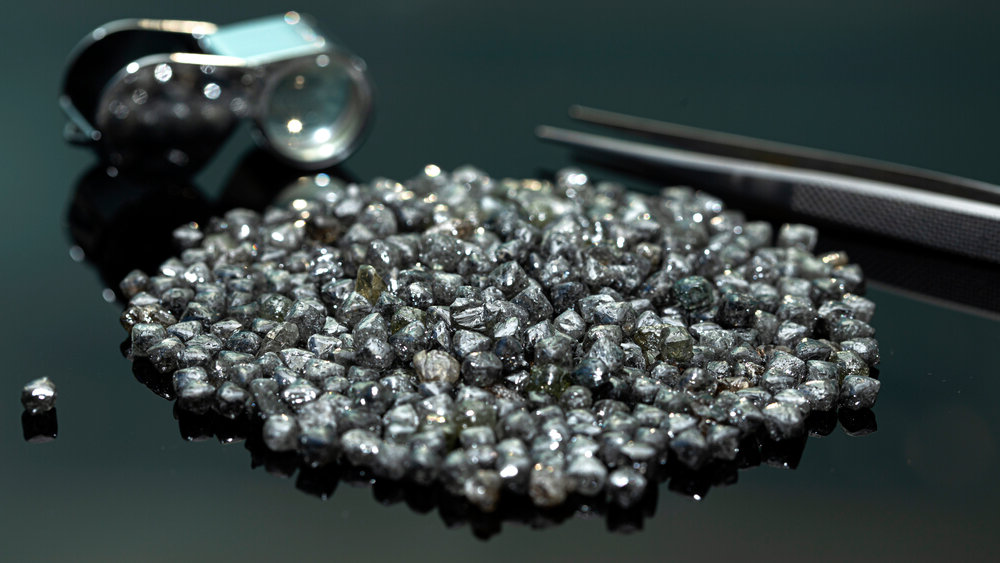

Ballas diamonds, for instance, are dense, spherical aggregates of diamond crystals, recognised for their irregular shape. These are primarily used in drilling and cutting applications.

Bort diamonds, however, are granular diamond fragments that are often recognised as ‘byproducts’ during gemstone extraction. Because they’re seen as ‘not suitable’ for use as gemstones, they are utilised by industries to aid grinding, polishing, and drilling, where their abrasive properties are particularly valuable.

Carbonado diamonds – also known as ‘black diamonds’ – are a type of natural polycrystalline diamond found in sedimentary rock formations. Characterised by their opaque black color, carbonado diamonds are even more hard, making them perfect for specialised industrial processes, where cutting and drilling must be done in challenging conditions.

Together, ballas, bort, and carbonado form a sort of ‘industrial trio’, with each of them offering distinct properties and applications that allow them to be used across various industrial sectors.

The Economics of Diamonds: Value Beyond the Vault

As we talked about before, industrial diamonds are far apart from diamonds used for jewelry. Unlike gemstones that are associated with luxury and investment, industrial diamonds are all about practicality and economics. In many ways, they are a different kind of investment – an investment in cost-efficiency for industries prioritising high performance, longevity, and versatility.

The cost of them can vary, of course, but the end goal is always to reduce costs and maximise productivity. Natural diamonds, for instance, will have an initial price tag of around $100 to $500 per carat, especially if they’re smaller and lower-quality. For industries needing larger and more quality diamonds, that price tag can rise to between $500 and $3,000.

But when you consider these diamonds will be extending tool life, providing higher cutting speeds, improving quality and precision, and reducing energy consumption – due to their superior efficiency and reduced heat generation – the money that’s ultimately saved down the line makes them an economic win.

When you bring in the subject of synthetic diamonds – which often range between $50 to $500 – it’s clear that diamonds are just as valuable for industrial purposes as they are for jewelry lovers. It’s just a different kind of value!

Looking Forward: The Future of Diamonds in Industry and Innovation

This is how industrial diamonds are being used right now, but you don’t need a crystal – or diamond – ball to foresee just how beneficial they’re going to be in the future. Over the last few years, there have been numerous advancements in diamond synthesis techniques, with new technologies enabling the production of larger, higher-quality synthetic diamonds that can be tailored for specific industrial needs.

There is also a growing utilisation of nanodiamonds – tiny diamond particles that can be used across multiple industries, including electronics, medicine, and environmental remediation. In electronics, nanodiamonds are being explored for their potential in quantum computing and high-performance sensors. In medicine, nanodiamonds are showing promise in tissue engineering, offering novel solutions for targeted therapy and diagnostics.

And speaking of the environment, industrial diamonds are playing a greater role in advancing sustainable practices, with many using nanodiamonds to explore new methods of water purification, solar energy conversion, and pollution detection. Some researchers are even investigating the use of diamonds in carbon capture technologies, designed to remove carbon dioxide from industrial emissions. Whether this will be possible remains to be seen, but diamonds are a crucial part of the innovative ideas that could make the world a better and greener place.

Beyond Jewelry: Revolutionary Uses of Industrial Diamonds

As the years go by and technology advances, we’re likely to see industrial diamonds being applied in even more industries, including biotechnology industries, medicine, and even space exploration – we said diamonds are well-suited for extreme environments, didn’t we? If you’re reading that and raising an eyebrow, remember how diamond-coated components can enhance durability.

When space exploration and aerospace grow, missions will become longer and more robust systems will be necessary. Diamonds could enhance the performance of spacecraft, satellites, and space instruments. They could even be our ticket to exploring Venus – a planet known for its harsh conditions and extreme temperatures. This is far off in the future, of course, but it’s still a possibility. The use-case of industrial diamonds is open for experimentation and, in many ways, we might not have scratched the surface of their potential.

Our Expert Take: The Lasting Legacy of Diamonds

Diamonds are a funny thing. They start as tiny carbon atoms, buried under the Earth unseen and unnoticed, before they start to grow. Over millions of years, immense pressure and heat make them transform into exquisite gemstones that not only captivate the hearts of millions around the world, but are used to revolutionise entire industries, shaping the backbone of technology and innovation. In effect, they have a lasting legacy that, like a diamond, will continue to grow for many generations to come.

7 Frequently Asked Questions About Industrial Diamonds

- Q: What are industrial diamonds?

- A: Industrial diamonds are diamonds primarily used for various industrial applications due to their hardness and thermal conductivity. They include natural diamonds unsuitable for jewelry and synthetic diamonds made for specific uses.

- Q: How are industrial diamonds made?

- A: Synthetic industrial diamonds are created through high-pressure high-temperature (HPHT) methods or chemical vapor deposition (CVD), simulating natural diamond formation conditions in a lab.

- Q: What are the main uses of industrial diamonds?

- A: They are used in cutting, grinding, drilling, and polishing tools for various industries, including electronics, mining, and construction.

- Q: Are all industrial diamonds synthetic?

- A: No, not all industrial diamonds are synthetic. Some are natural diamonds that are not of gemstone quality and are thus used for industrial purposes.

- Q: How do the prices of industrial diamonds compare to gem-quality diamonds?

- A: Industrial diamonds are generally less expensive than gem-quality diamonds due to their abundance and the fact that aesthetic qualities are not a priority.

- Q: Can industrial diamonds be transformed into gem-quality diamonds?

- A: Through HPHT treatment, some industrial diamonds can be altered to improve their color or clarity for jewelry use, but this doesn’t apply to all industrial diamonds.

- Q: Where are most industrial diamonds sourced?

- A: While Africa is a significant source of natural industrial diamonds, synthetic industrial diamonds are produced worldwide, with leading contributions from China, the U.S., and Russia.

Dive into Jeweler AI: Unearth the perfect diamond engagement ring with precision and ease. Your journey to brilliance begins here.

FOLLOW-UP GUIDE SERIES