Nanodiamonds: Discover the Unsung Heroes of Jewelry!

By Gary A.

Edited by Olivia H.

Published Jul 29, 2024

Edited on Dec 18, 2024

Nanodiamonds might be too small for jewelry, but their unique properties are revolutionizing industries, from cutting-edge technology to advanced manufacturing. Here’s why they matter.

Navigate This Guide:

- 5 Quick Tips – Nanodiamonds Are Too Small for Engagement Rings: Opt for Melee Diamonds Instead

- Introduction

- What Exactly Are Nanodiamonds?

- The Genesis of Nanodiamonds: From Explosions to Brilliance

- The Hidden Powers of Nanodiamonds in the Diamond Industry

- The Economic Landscape of Nanodiamonds

- The Ethical and Environmental Impact

- Our Expert Take: The Future of Nanodiamonds and their Role in Jewelry

- 11 Frequently Asked Questions About Nanodiamonds

Before we dive deeper into the specifics, here are some practical tips to help guide your decision-making process:

5 Quick Tips – Nanodiamonds Are Too Small for Engagement Rings: Opt for Melee Diamonds Instead

While nanodiamonds may dominate industrial applications with their remarkable properties, their closest relatives in the jewelry world are melee diamonds. These tiny gems, often used to accentuate the beauty of engagement rings and other fine jewelry, require a discerning eye to choose wisely. Here are essential tips to consider when selecting melee diamonds for that perfect engagement ring.

Tip 1: Understanding Melee Diamonds

Melee diamonds are small diamonds, typically less than 0.2 carats, used to enhance the design and overall sparkle of diamond jewelry. They bring a piece to life, adding luminosity and depth that larger stones alone cannot achieve. When considering melee diamonds for an engagement ring, it’s crucial to understand their role and how they complement the main stone.

Tip 2: Examine the Quality Consistency

When melee diamonds are incorporated into a piece of jewelry, consistency in quality is key to achieving a harmonious and dazzling effect. Here are practical tips on ensuring quality consistency:

Look for Uniformity in Color: Melee diamonds should match in color, not only with each other but also with the center stone. A significant variation can detract from the ring’s beauty, causing it to look disjointed.

Check for Symmetrical Cutting: Well-cut melee diamonds will share similar facets and proportions, enhancing the ring’s overall brilliance. Inconsistent cuts can result in a patchy light reflection, diminishing the piece’s sparkle.

Inspect Clarity Carefully: While melee diamonds are small, inclusions can still impact their sparkle. Choose diamonds with similar clarity grades to ensure that none detract from the ring’s appearance.

Tip 3: Prioritize Matching Over Size

In the quest for the perfect engagement ring, one might think bigger is always better. However, with melee diamonds, the emphasis should be on matching and harmony rather than size.

Harmony with the Main Stone: Ensure the melee diamonds do not overshadow the centerpiece. Their role is to complement, not compete.

Consistent Scintillation: Smaller, well-matched melee diamonds can often produce more scintillation than larger, poorly matched ones. Opt for stones that enhance the ring’s overall brilliance.

Tip 4: Consider the Setting Style

The setting of melee diamonds can significantly affect the ring’s final look and feel. Different settings can offer varying degrees of sparkle and protection for the diamonds.

Shared Prong Settings: This setting allows for maximum light exposure but offers less protection to the melee diamonds’ edges.

Pave Settings provide a seamless flow of sparkle and more protection for the diamonds, making them a popular choice for engagement rings.

Bezel Settings: While offering the most protection by encircling each diamond in metal, this setting may slightly reduce the stones’ visible surface and, consequently, their sparkle.

Tip 5: Pay Attention to the Ring’s Overall Design

The design of the ring should not only reflect personal style but also ensure the longevity and durability of the melee diamonds.

Balance and Proportion: A well-designed ring will have a pleasing balance, ensuring that the melee diamonds enhance rather than overwhelm the piece.

Durability of the Setting: Consider the daily wear and tear the ring will endure and choose a design that secures the melee diamonds firmly.

Now that you’ve got these practical tips, use Jeweler AI below to find the perfect engagement ring that suits your style and budget:

Introduction

It’s quite a moment when you finally put a diamond ring on the finger and turn it towards the light. It seems almost like an explosion is happening: a great fire of brilliance that flashes and bends whichever way you turn it. Some people will spend thousands on procuring that moment. The higher the carat, and the better the grading of color, clarity, and cut, the more sparkle you’re going to see.

But what a lot of people don’t know is that the 4Cs are not the only things to determine how impactful this moment will be. By that we mean, it’s not just the one diamond involved in an incredible engagement ring. There are, in fact, many. There are diamonds hiding beneath the surface that not a lot of people know about. Silent but glistening. The unsung heroes of the jewelry world. The title of this article might have given it away!

What Exactly Are Nanodiamonds?

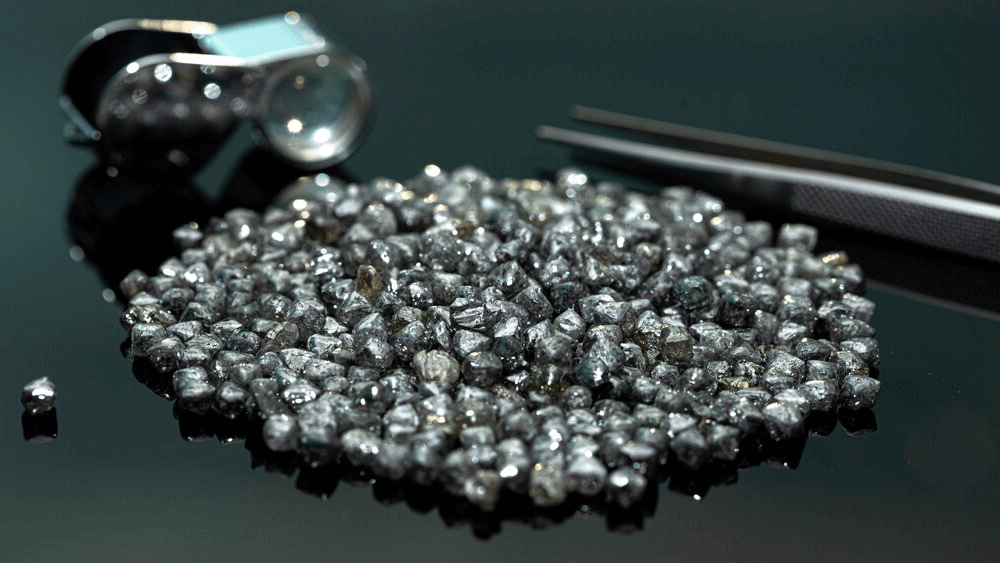

We are of course talking about nanodiamonds. As the name suggests, these are diamonds that are incredibly small in scale – mere nanometers in size, thousands of times thinner than a human hair. They share the same crystalline structure as conventional diamonds found in nature, but their minuscule dimensions give them some truly unique properties that set them apart.

At the nanoscale, these diamonds have an exceptionally high surface area relative to their volume, which means a higher proportion of their atoms are exposed to the surface compared to bulk diamonds. As a result, these diamonds have enhanced chemical reactivity, optical characteristics, and physical behaviours.

While they’re not the shining centrepiece gemstone – you’d have to have a pretty powerful magnifier if you want that to be the case! – they are often integrated into the jewelry production process, with the potential to elevate brilliance, dispersion, and the overall optical performance of your chosen diamond. So while the romantic significance of an engagement ring might lie in that single, flawless diamond sparkling atop the setting, its radiance could very well be down to millions of nanodiamonds – all of them tiny unsung heroes working behind the scenes!

The Genesis of Nanodiamonds: From Explosions to Brilliance

So how exactly are nanodiamonds made? Well, while traditional diamonds emerge from the high temperature and pressure conditions deep underground, nanodiamonds have a bit more of an explosive origin story. The production of nanodiamonds typically involves harnessing extreme environments like detonations or vapour deposition techniques, working to coax carbon atoms into rearranging their crystalline structure.

One common method to do this is known as CVD. Here, a hydrocarbon gas mixture is subjected to high temperatures in a vacuum chamber. As the gases break down, the carbon atoms rearrange into diamond structures, with each nanodiamond growing one layer at a time to form a diamond film coating on the chamber walls.

Detonation Nanodiamonds: A Spark in the Dark

The other – more explosive – approach is known as detonation synthesis. This starts with a mixture of explosives and carbon-rich compounds like RDX or TNT. The explosives are carefully detonated inside a sealed chamber, and the intense environment causes carbon atoms to rearrange themselves in the sooty residue.

The soot is then removed from the chamber and the nanodiamond particles are extracted from it. Although it’s more speedy – and violent! – the detonation process essentially mimics the extreme heat and pressure conditions that form larger diamonds, shocking carbon atoms into diamond nanocrystals with just a spark in the dark.

The Hidden Powers of Nanodiamonds

So we’ve talked a little bit about how these diamonds are made, but what are their hidden powers? Nanodiamonds can be utilised for a number of different purposes, including diamond coating, cutting, and numerous industrial applications that transcend the diamond industry.

Revolutionising Manufacturing: The Industrial Might of Nanodiamonds

As of 2024, nanodiamonds are being used across multiple industries, with one of the most prescient being the construction industry. Here, nanodiamonds are used to create ultra-hard cutting tools, lubricants to reduce friction and wear on machinery – while also improving performance – and tougher coatings for protective equipment. They have also found a lot of uses in the EV industry, with nanodiamonds improving the performance and durability of electric vehicle batteries, motors, and other components.

The Future is Bright: Nanodiamond Batteries

Speaking of batteries, this is arguably where nanodiamonds have been most beneficial, as they’ve helped to improve battery performance and lifespan. For electrode materials, lithium battery anodes, electrolyte additives, and more, nanodiamonds have been shown to improve their capacity, energy density, and cycle life, while also reducing costs and the overall environmental impact. Research is still ongoing in these areas, but the applications of nanodiamonds are sure to make an even bigger impact as time moves on.

The Hidden Powers of Nanodiamonds in the Diamond Industry

Those are just some of the ways nanodiamonds are used outside of the diamond industry, but what about inside? We’ve mentioned that they’re used for coating and cutting, but what exactly does this mean?

Adding Sparkle: How Nanodiamonds are Used to Elevate Brilliance

When it comes to polishing and cutting, nanodiamonds are used as abrasives to enhance the tools used to cut and coat the diamonds. By applying nanodiamond coatings to cutting tools, the thermal conductivity is increased, and this helps to dissipate the heat and reduce the thermal degradation down the line.

They can also be used to treat gemstones, enhancing their fire and brilliance. Treating gemstones with nanodiamonds improves their scratch resistance, making them more durable and less prone to damage, and through a process known as laser treatment, jewellers can fill microscopic imperfections to provide better light reflection, leading to that beautiful, brilliant sparkle that we talked about earlier. In essence, nanodiamonds not only improve the functional aspects of diamond processing but also elevate the aesthetic qualities of the diamond itself, making it even more of an invaluable asset in the diamond industry.

The Economic Landscape of Nanodiamonds

One of the best things about nanodiamonds is the economic benefit – as mentioned previously, their use in polishing and cutting tools leads to an extended tool life, reducing the frequency of replacements. And this is the same across every industry. Through utilising nanodiamonds, products can not only be refined, but the process of creating those products can be streamlined.

Nanodiamond Price: The Cost of Innovation

Of course, the cost of producing and purchasing nanodiamonds is high – high enough that they do not receive regular use, but that’s the cost of innovation. Typically, if nanodiamonds are created through detonation synthesis, the costs range between $100 to $1,000 per gram, with that cost increasing to $500 to $3,000 if they are produced through CVD.

The cost of buying depends on the grading of the diamonds, including their purity, size and surface modifications. Typically, commercial-grade nanodiamonds sell for around $1,000 per gram, while high-purity nanodiamonds sell for $3,000. Functionalized nanodiamonds – nanodiamonds that have been chemically altered to enhance their performance – cost around $5,000 and specialised nanodiamonds can often exceed $5,000.

The Ethical and Environmental Impact

Reducing the frequency of tool replacements – as well as increasing battery life – is not just a positive from a cost perspective, it has positive environmental aspects too. By reducing tool replacements, unneeded waste is minimised, with tools and coatings also requiring less energy for operation due to their thermal conductivity and wear resistance. The process of producing nanodiamonds themselves can also be seen as environmentally friendly, with most producers utilising carbon waste materials rather than extracting new raw materials – thereby turning potential pollutants into valuable resources.

Sustainable Sparkles: Eco-friendly Aspects of Nanodiamonds

We should also mention the potential of nanodiamonds in green technologies. For instance, research is currently ongoing in the use of nanodiamonds for water purification systems, where their high surface area and reactivity could help remove contaminants far more effectively. Nanodiamonds are also being incorporated into the design of solar cells and fuel cells, as well as soil remediation and air filtration, improving efficiency and reducing negative environmental impacts across the board. It’s not just gemstones they help to sparkle – it’s planet Earth itself!

Our Expert Take: The Future of Nanodiamonds and their Role in Jewelry

When it comes to the future of nanodiamonds, it’s certainly looking bright – no pun intended! Driven by advancements in nanotechnology and sustainability solutions, more and more industries are starting to implement them, not least the diamond industry, which might even start utilising nanodiamonds to aid in customisation and creative expression. As technology continues to advance and the world grows even more sustainable, we’re sure the benefits of nanodiamonds are only going to get more recognised. And we can’t wait to see what happens next!

11 Frequently Asked Questions About Nanodiamonds

- Q: What are nanodiamonds?

- A: Nanodiamonds are diamonds that exist on a nanometric scale, typically measuring just a few nanometers in diameter (1 nanometer is one-billionth of a meter). Despite their minuscule size, they possess many of the same characteristics as larger diamonds, such as hardness and thermal conductivity.

- Q: How are nanodiamonds made?

- A: Nanodiamonds can be produced through several methods, with detonation synthesis being the most common. This process involves detonating carbon-containing explosives in a controlled environment, resulting in the formation of nanodiamonds amidst the explosion’s soot.

- Q: What makes nanodiamonds unique?

- A: Their unique combination of diamond-like properties at a nanoscale makes them exceptionally versatile. Nanodiamonds exhibit remarkable hardness, high thermal conductivity, and robust chemical stability, alongside unique optical and electronic properties due to their size.

- Q: Are nanodiamonds real diamonds?

- A: Yes, nanodiamonds are real diamonds. They are composed of carbon atoms arranged in a diamond crystal lattice, similar to conventional diamonds but at a much smaller scale.

- Q: What are the applications of nanodiamonds?

- A: Nanodiamonds have a wide range of applications across various fields, including electronics, medicine, and manufacturing. They are used in drug delivery systems, as additives in lubricants and polymers, in the fabrication of wear-resistant coatings, and in quantum computing research, among other applications.

- Q: Can nanodiamonds be used in jewelry?

- A: While nanodiamonds are technically real diamonds, their microscopic size makes them unsuitable for use as gemstones in traditional jewelry settings. They are, however, used in industrial applications related to the jewelry industry, such as polishing and cutting tools.

- Q: Are nanodiamonds safe?

- A: Nanodiamonds are considered safe for various applications, including in biomedical fields. However, like any nanomaterial, their safety depends on how they are used and processed. Research into their biocompatibility and environmental impact is ongoing to ensure they can be used safely across all applications.

- Q: How do the properties of nanodiamonds compare to those of larger diamonds?

- A: Nanodiamonds share many of the physical properties of larger diamonds, such as hardness and thermal conductivity. However, their nanoscale size also endows them with unique properties, such as enhanced optical and electronic behaviors, which larger diamonds do not exhibit.

- Q: What is the future of nanodiamond research?

- A: The future of nanodiamond research is promising, with ongoing studies exploring their potential in electronics, quantum computing, and advanced medical therapies. Innovations in production methods and applications are expected to expand their use in various industries.

- Q: How much do nanodiamonds cost?

- A: The price of nanodiamonds varies depending on the production method, purity, and quantity. While they are generally less expensive than gem-quality diamonds, high-purity nanodiamonds for specific industrial or research applications can be costly.

- Q: Are nanodiamonds suitable for jewelry?

- A: No, nanodiamonds are not suitable for use as gemstones in jewelry due to their microscopic size. The closest equivalents in the jewelry world are melee diamonds, which are small diamonds used to accentuate larger stones in pieces of jewelry. These melee diamonds, though significantly larger than nanodiamonds, serve to enhance the overall sparkle and aesthetic appeal of jewelry pieces.

Discover the future with Jeweler AI: Your gateway to the revolutionary world of Pave, Halo and bespoke engagement rings with Melee Side Stones.

FOLLOW-UP GUIDE SERIES